Indonesia Kitchen Cabinet Factory

In the third quarter of 2019, our dedicated kitchen cabinet factory in Jakarta, Indonesia, began its journey, exclusively serving the US market. This state-of-the-art facility, mirroring the production machinery model of our esteemed kitchen cabinet manufactory in China, upholds our unwavering commitment to consistency in manufacturing standards. To ensure our operations in Indonesia maintain the same level of efficiency and quality, we transferred our skilled and experienced management team from China to this factory. This strategic move, alongside the replication of our headquarters’ highly automated system, significantly reduces the need for labor, embodying our dedication to innovation and excellence in the kitchen cabinet manufacturing industry.

Factory Showcase

China Kitchen Cabinet Factory

Founded in 2008, Guangdong Baishan Furniture Co., Ltd. (PA Home) is a top kitchen cabinet factory. It’s in a leading building materials city. The factory spans over 40,000 square meters. Baishan excels in whole-house furniture customization globally. Its range includes kitchen cabinets, wardrobes, and furnishings. This diversification positions Baishan as a home furnishing industry leader. The company uses the advanced German Homag line in its manufactory. This ensures automated production meeting international standards. Baishan’s kitchen cabinet manufactory is committed to quality. It meets the needs of global customers, highlighting its international market presence.

Automatic Industry

Factory

production capacity per year

Kitchen Cabinet Factory Quality Contolling Systerm

AUTOMATIC PRODUCTION LINE

The German Homag flexible production line adopts the three-pronged approach of automation, information and refinement for the product manufacturing process, which ensures the product is best in every link from design, cutting, surface finishing, assembly, transportation, installation to service, It not only saves labor costs, but also improves production efficiency, greatly reduces errors, and better shortens the delivery time.

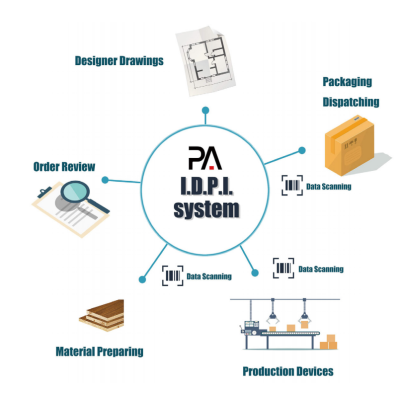

INTELLIGENT DESIGN AND PRODUCTION SYSTEM

We’ve invested millions in our Intelligent Design and Production System (IDPS), an integrated platform for design, production, and quality control that upholds PA’s competitive edge. Here’s how it streamlines the process:

- Designers upload plans directly to the IDPS.

- The system converts plans to production directives, minimizing human error.

- Panels are QR-coded; machines read and execute production commands automatically.

- Scanning QR codes in sorting and packing ensures accuracy and project completeness.

This innovative system significantly cuts down on manual input and errors, achieving an impressive error rate of below 0.1%.

ERP SYSTEM

PA Home leverages an ERP System to establish a standardized orchestration, streamlining operations across sales, order placement, purchasing, manufacturing, inventory management, store management, and financial management. This system ensures that each role and process is meticulously supervised, aiding management layers in overseeing the entire sales and production cycle. Under the guidance of the ERP system, PA Home can guarantee accuracy, timeliness, and efficiency throughout the production process. This approach significantly boosts PA’s management quality and enhances the competitiveness of its products.

SUPPLY CHAIN SYSTEM

PA develops the advantage of resources integration to enlarge the supply chain, and hope to set up strategic partnership with top raw material suppliers from technique, panel materials to hardware accessories so we could ensure the quality for each small process. For example, we have close partnerships with Austria Blum, Germany Homag, Hettich, Rehao, China DTC to pursue each qualified detail.